Engineering

With the diverse composite technologies it is important to carefully design, test and produce the right composite product. We recommend to carry out this development process together with the customer to receive the best results per milestone. Below is an overview of the development process you can expect from us:

We use a software-supported up-to-date quality laboratory to characterize raw materials, semi-finished and finished products:

- X-Ray non-destructive-testing (NDT)

- 3D coordinate-measuring machine (CMM)

- Instron test bench

- Brookfield viscometer

3D measurements

For product release we have a brand-new 3D automated CMM at our disposal. After programming, we can compare the dimensional deviations directly with the original design. In addition, on request we can send automatically generated measurement reports to the customer.

100% X-ray control / NDT

For a 100% guarantee on our medical products, we check all critical products under X-Ray. In this way we meet the highest requirements of X-ray radiolucency and homogeneity. The maximum dimensions for this inspection and 2D NDT tests are 75 cm wide and 20 cm high.

100% inspection

Every product is meticulously checked by our employees. This includes taking measurements and perfomring a visual inspection.

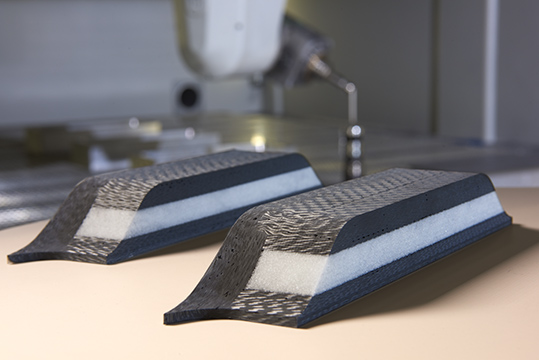

Prototypes

Building prototypes is simply seeing first, then believing. Within 3 weeks we can produce functional prototypes with our in-house facilities (5-axis CNC milling, CAD design & optimization, soft-tooling, vacuum infusion, lacquering and post-measurement). We always see prototypes as a stepping stone to the final product, that's why we take manufacturability into account during development.

|

|